|

Polyurethane

RTV Mold Rubber

|

The 74-30 is

the softest of our RTV rubbers. These rubbers can

be used for making

durable, easy releasing molds for casting gypsum

plasters, waxes, cement, epoxy resins

polyester resins along with urethane and acrylic.

Proper mold

release is

needed to

insure easy parting from the mold.

|

|

|

|

|

74-30

RTV Liquid Urethane

Mold Rubber

Mixed

1 Part A to 1 Part B

Working Time: 30 Minutes

Demold Time: 24 Hours

Hardeness, Shore A: 30

|

|

Info:

Our softest polyurethane. Fairly soft and

stretchable. Good for molds with complex

shapes or detail that might require an

easily flexible rubber.

|

|

|

|

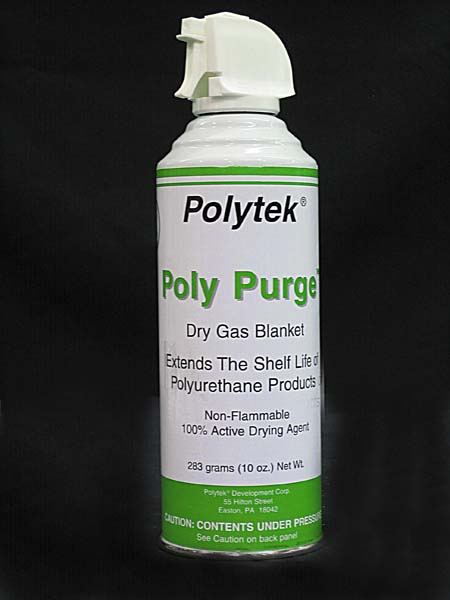

Mold

Release Info: For releasing this

rubber from a smooth non-porous

original/plug an aerosol such as

Poly-2300

or Stoner

is suitable. Porous objects such as

plaster, concrete or wood should first be

sealed to create a smooth surface from

which to apply the mold

release.

|

|

74-30 Is Available in

2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-74301

|

16oz

Kit (8oz A + 8oz B)

|

$16.85

|

|

POLY-74302

|

32oz

Kit (2

LBs)

|

$28.50

|

|

POLY-74303

|

2

Quart Kit (4

LBs)

|

$49.00

|

|

POLY-74304

|

1

Gallon Kit (8

LBs)

|

$83.50

|

|

POLY-74305

|

2

Gallon Kit (16

LBs)

|

$140.50

|

|

POLY-74306

|

10

Gallon Kit (80

LBs)

|

$524.00

|

Kit sizes above show total volume included in

kit

with total weight in parentheses.

|

|

|

|

75-60

RTV Liquid Urethane

Mold Rubber

Mixed

1 Part A to 1 Part B

Working Time: 15 Minutes

Demold Time: 12 Hours

Hardness, Shore A: 60

|

|

Info:

A medium hardness polyurethane. Similar in

hardness to a pencil eraser. The cured

rubber will flex but has very little

stretchability.

|

|

|

|

Mold

Release Info: For releasing this

rubber from a smooth non-porous

original/plug an aerosol such as

Poly-2300

or Stoner

is suitable. Porous objects such as

plaster, concrete or wood should first be

sealed to create a smooth surface from

which to apply the mold

release.

|

|

75-60 Is Available in

2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-75601

|

16oz

Kit (8oz A + 8oz B)

|

$16.85

|

|

POLY-75602

|

32oz

Kit (2

LBs)

|

$28.50

|

|

POLY-75603

|

2

Quart Kit (4

LBs)

|

$49.00

|

|

POLY-75604

|

1

Gallon Kit (8

LBs)

|

$83.50

|

|

POLY-75605

|

2

Gallon Kit (16

LBs)

|

$140.50

|

|

POLY-75606

|

10

Gallon Kit (80

LBs)

|

$524.00

|

Kit sizes above show total volume included in

kit

with total weight in parentheses.

|

|

|

|

|

75-80

RTV

Liquid Urethane Mold

Rubber

Mixed

2 Parts A to 1 Part B

Working Time: 45 Minutes

Demold Time: 24 Hours

Hardness, Shore A: 80

|

|

Info:

A very hard polyurethane rubber. Very

close in hardness to a car tire. Best for

flat molds with minimal detail. Also can

be used for certain concrete stamping

applications.

|

|

|

|

Mold

Release Info: For releasing this

rubber from a smooth non-porous

original/plug an aerosol such as

Poly-2300

or Stoner

is suitable. Porous objects such as

plaster, concrete or wood should first be

sealed to create a smooth surface from

which to apply the mold

release.

|

|

75-80 Is Available in

2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-75801

|

24oz

Kit (16oz A + 8oz B)

|

$25.00

|

|

POLY-75802

|

48oz

Kit (3

LBs)

|

$43.50

|

|

POLY-75803

|

3/4

Gallon Kit (6

LBs)

|

$72.50

|

|

POLY-75804

|

1 1/2

Gallon Kit (12

LBs)

|

$120.50

|

|

POLY-75805

|

3

Gallon Kit (24

LBs)

|

$212.00

|

|

POLY-75806

|

15

Gallon Kit (120

LBs)

|

$788.00

|

Kit sizes above show total volume included in

kit

with total weight in parentheses.

|

|

|

|

|

75-90

RTV

Liquid Urethane Mold

Rubber

Mixed

2 Parts A to 1 Part B

Working Time: 10 to 15 Minutes

Demold Time: 24 Hours

Hardness, Shore A: 90

|

|

Info:

Polytek 75-90 is our hardest and strongest

polyurethane rubber. It is used for making

tough, durable molds, liners and stamps

for casting, forming and texturing

concrete. This firm rubber is also popular

for making industrial parts, rollers,

gaskets, bumbers, pads, and more.

If tinting this rubber is desired, we sell

a selection of tinting colors here:

COLORED PIGMENTS

|

|

|

|

Mold

Release Info: For releasing this

rubber from a smooth non-porous

original/plug an aerosol such as

Poly-2300

or Stoner

is suitable. Porous objects such as

plaster, concrete or wood should first be

sealed to create a smooth surface from

which to apply the mold

release.

|

|

75-90 Is Available in

2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-75901

|

24oz

Kit (16oz A + 8oz B)

|

$26.75

|

|

POLY-75902

|

48oz

Kit (3

LBs)

|

$46.00

|

|

POLY-75903

|

3/4

Gallon Kit (6

LBs)

|

$77.00

|

|

POLY-75904

|

1 1/2

Gallon Kit (12

LBs)

|

$127.00

|

|

POLY-75905

|

3

Gallon Kit (24

LBs)

|

$223.00

|

|

POLY-75906

|

15

Gallon Kit (120

LBs)

|

$869.00

|

Kit sizes above show total volume included in

kit

with total weight in parentheses.

|

|

|

|

Polygel 35

Self Thickening RTV Liquid

Urethane Rubber For Brush-On Molds

|

|

Polygel mold rubbers

consist of two liquids, Part A and Part B which after mixing

immediately gel to a brushable or trowellable consistency,

then cure overnight at room temperature to a flexible, tough

RTV rubber. They are ideal for molds built up with a brush,

spatula or spray, Polygel mold rubbers are recommended for

evaluation as a mold material for plaster, cement and waxes,

as well as for limited casting with polyester epoxy and

polyurethane resins.

|

Poly

Gel 35

Mixed

1 Part A to 1 Part B

Hardness, Shore A: 35

Working Time: 8 to 10 Minutes

Demold Time: 24 Hours

|

|

Info:

A self-thickening brushable mold

rubber. Used primarily for blanket molds.

Usually requires a mother mold backing to

support the mold after it is made. Plaster

or fiberglass and resin are commonly used

for mother molds.

|

|

Available

in 2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-GEL351

|

16oz

Kit (8oz A + 8oz B)

|

$17.25

|

|

POLY-GEL352

|

32oz

Kit (2

LBs)

|

$29.00

|

|

POLY-GEL353

|

2

Quart Kit (4

LBs)

|

$49.50

|

|

POLY-GEL354

|

1

Gallon Kit (8

LBs)

|

$84.50

|

|

POLY-GEL355

|

2

Gallon Kit (16

LBs)

|

$146.50

|

|

POLY-GEL356

|

10

Gallon Kit (80

LBs)

|

$598.00

|

|

|

|

|

PlatSil 73 Series RTV Silicone Mold

Rubbers

|

|

PlatSil rubbers are

platinum-cured(also known as addition-cure), room

temperature curing silicones(RTV) that are used to make

flexible, high-strength molds and parts. PlatSil molds are

often selected over other mold materials because of their

excellent release properties. They exhibit long mold life

and low shrinkage on cure.

PlatSil molds are excellent

for casting polyurethane, epoxy resins, polyester resins,

polyurethane foam, wax, plaster, soap, concrete, and more.

Release agent is generally not needed to cast any of these

materials. Should not be used with silicone based releases

or lubricants.

|

73-25

Plat-Sil

RTV Silicone Mold

Rubber

Mixed

1 part B to 1 part A

Hardness, Shore A: 25

Pour Time: 15 min.

Demold Time: 6 Hours

Cured Color: Light Green

|

|

*Special

Note: This Platinum Cure silicone

works extremely well for casting polyester

resins such as our Silmar 41. It will

leave much less tackiness on the surface

of the cured resin when removed from the

mold*

Info: Polytek PlatSil 73-25 is a very

easy to use 1:1 ratio. It is a very soft

and stretchable silicone rubber. No mold

release is required, however when making a

mold from a porous surface such as wood

the surface should be sealed or painted to

avoid possible sticking.

|

|

Available

in 2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-7325-1

|

2LB

Kit

(approx. 1 Quart)

|

$

56.00

|

|

POLY-7325-2

|

4LB

Kit

(approx. 2 Quarts)

|

$

92.00

|

|

POLY-7325-8

|

8LB

Kit

(approx. 1 Gallon)

|

$

177.00

|

|

POLY-7325-16

|

16LB

Kit

(approx. 2 gallons)

|

$

329.00

|

|

POLY-7325-80

|

80LB

Kit

(approx. 10 gallons)

|

$

1,400.00

|

|

*FOOD GRADE RATED*

(see

details

below)

73-45 Plat-Sil

RTV Silicone Mold

Rubber

Mixed

10 parts B to 1 part A

Hardness, Shore A: 45

Pour Time: 40 min.

Demold Time: 16 Hours

Cured Color: Green

|

|

Info:

Polytek PlatSil 73-45 is a two-part,

platinum-cure liquid silicone system.

Mixed at a 10:1 ratio by weight. This

system has a medium grade of

hardness(Shore: A45) and

stretchability. No mold release is

required, however when making a mold from

a porous surface such as wood the surface

should be sealed or painted to avoid

possible sticking. See details below

regarding use as a mold in food

processing.

*Special Note: This Platinum

Cure silicone works extremely well for

casting polyester resins such as our

Silmar 41. It is also good for casting

plasters, polyurethane resins, acrylic

resins, and epoxy. Platinum cure silicone

will leave much less tackiness on the

surface of the cured polyester resin when

removed from the mold*

|

|

*FOOD GRADE RATED*

(see

details below)

Available in 2 Part Kits

|

Cat

No.

|

Description

|

Price

|

|

POLY-P7345-1

|

1LB

Kit

(approx. 0.8 Pint)

|

$

39.90

|

|

POLY-P7345-2

|

2LB

Kit

(approx. 0.8 Quart)

|

$

70.50

|

|

POLY-P7345-9

|

9LB

Kit

(approx. 0.8 gallons)

|

$

161.00

|

|

POLY-P7345-44

|

44LB

Kit

(approx. 4 gallons)

|

$

797.00

|

|

|

•Food

Grade Rated

Silicone•

|

|

Details:

•Plat-Sil 73-45 has been tested by an

independent laboratory and was found to

comply with 21 CFR 177.2600 (as

published in the Code of Federal

Regulations) for rubber articles

intended for repeated use food contact

surfaces when accurately measured,

thoroughly mixed, and fully cured.

Compliance with this regulation also

requires that the user of this material

must also comply with all applicable

FDA requirements.

•The 73-45 is commonly used to make

ice trays, baking molds/trays, chocolate

molds, butter molds, fondant molds,

gaskets and seals for food processing

environments, and other culinary and food

processing applications.

•Review product Technical

Bulletin

above for processing instructions.

•Prior to using silicone molds or

parts for food applications, thoroughly

wash the mold or part with a water and

dishwashing detergent, then rinse and

applow to dry. When applicable, thoroughly

wash the mold or part in between batches.

If baking, do not expose the mold to

temperatures above

400°F.

|

|

|

|

|